3D Printing and Additive Manufacturing Capabilities

The addition of 3D and Additive Manufacturing options is another example where Century Fasteners provides value added services to help our customers save capital, time, and resources.

What is Additive Manufacturing?

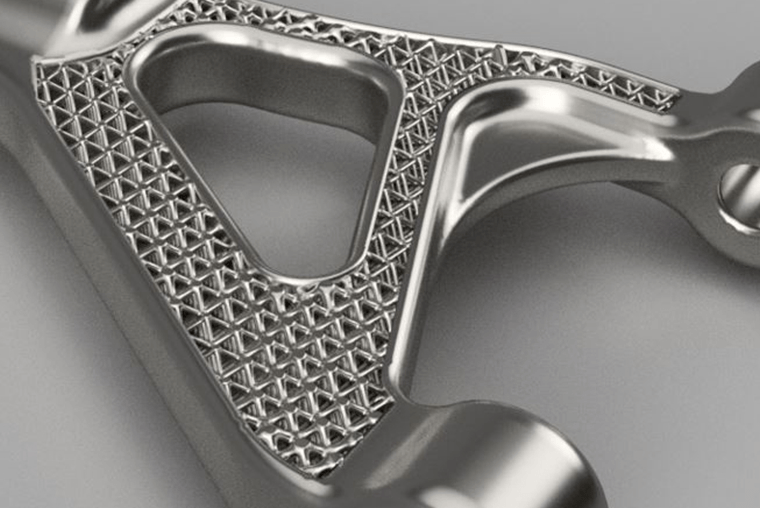

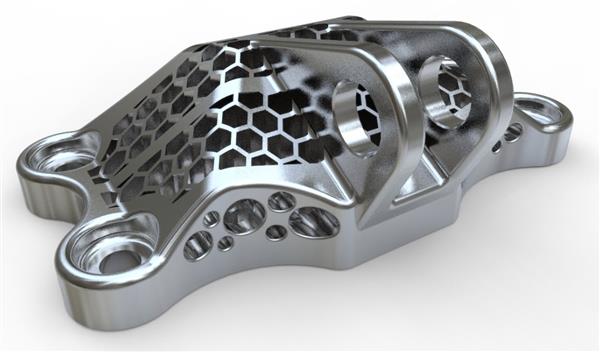

Additive manufacturing (AM) is defined as the process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies. Synonyms are additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, and free-form fabrication. The primary applications of additive fabrication are design/modeling, fit and function prototyping, and direct part production. Around the world, AM is changing the way organizations design and manufacture products. When used correctly, it can save impressive amounts of time and money. Companies maintain that AM has helped trim weeks, even months, of design, prototyping, and manufacturing time, while avoiding costly errors and enhancing product quality. AM is being used to fabricate end-use products in aircraft, military, medical, automotive, aerospace, transportation and many other industries.

Key Benefits of 3D Printing and Additive Manufacturing

- Ease of Creating Complex Pieces

- Better Efficiency in Prototyping

- Better Efficiency in Smaller Product Runs

- Increased Speed to Market

- Mitigate Production Risk

- Virtually Zero Waste!

How Does it Work?

The clue to the basics of additive manufacturing; rather than producing an end result by taking material away, it adds to it instead. Traditional manufacturing methods involve a material being carved or shaped into the desired product by parts of it being removed in a variety of ways. Additive manufacturing is the pole opposite; structures are made by the addition of thousands of minuscule layers which combine to create the product. The process involves the use of a computer and special CAD software which can relay messages to the printer so it “prints” in the desired shape. Suitable for use with a range of different materials, the cartridge is loaded with the relevant substance and this is “printed” into the shape, one wafer-thin layer at a time. These layers are repeatedly printed on top of each other, being fused together during the process until the shape is complete.

Century is your partner in production, and now, with this new program, this means providing a curated team of manufacturers in the exciting field and fast paced world of additive manufacturing. If your company is already using 3D printing, we can add material and process capabilities you may not have in house. If it is new to you, we can add this manufacturing dimension to you and your customers without direct investment in this emerging technology.

Take a moment and contact Century to bring this most advanced manufacturing capabilities to your door. Let us show you how we can work together to quickly provide your company with lower cost, high quality products when you need them.

For further assistance contact a Century Fasteners branch or a Regional Sales Manager.